How Dry Ice Cleaning Can Transform Engine Bay Detailing

Maintaining the cleanliness of an engine bay is crucial for vehicle performance and longevity. Traditional cleaning methods like steam or chemical degreasers can be effective but often risk damaging delicate components or leaving residues. Enter dry ice cleaning — a revolutionary, non-abrasive method that transforms engine bay detailing. This guide explores how dry ice cleaning works, its benefits over traditional methods, and why it’s the preferred choice for professional detailers.

What is Dry Ice Cleaning?

Dry ice cleaning, or CO₂ blasting, is an innovative process that uses compressed air to propel dry ice pellets onto surfaces. The process effectively removes dirt, grease, and grime without causing damage.

How It Works: The extreme cold of dry ice pellets creates a thermal shock that lifts contaminants, while the dry ice sublimates (turns into gas) on impact, leaving no residue.

Why It’s Unique: Unlike traditional methods, dry ice cleaning does not involve water or chemicals, making it safe for sensitive engine components.

Advantages of Dry Ice Cleaning for Engine Bays

1. Safe for Delicate Components

Engine bays house a variety of sensitive parts, such as wiring, sensors, and connectors. Using water or harsh chemicals can damage these components.

Dry ice cleaning is non-abrasive and moisture-free, making it ideal for cleaning delicate surfaces such as:

Electrical wiring and connectors.

Plastic and rubber parts.

Painted surfaces.

2. Effectively Removes Grease and Grime

Dry ice cleaning excels at eliminating tough contaminants like oil buildup, grease, and grime that accumulate in engine bays over time. It also effectively removes brake dust from wheels and other auto components.

Unlike steam cleaning, dry ice blasting doesn’t require drying time.

It reaches hard-to-access areas that traditional methods often miss.

3. Eco-Friendly Solution

Traditional cleaning methods often rely on chemical degreasers that can harm the environment. Chemical cleaning solutions are not only environmentally damaging but can also be potentially harmful to vehicle surfaces.

Dry ice cleaning uses non-toxic CO₂ pellets that sublimate into the atmosphere without creating waste.

Eliminates the risk of chemical runoff or disposal concerns.

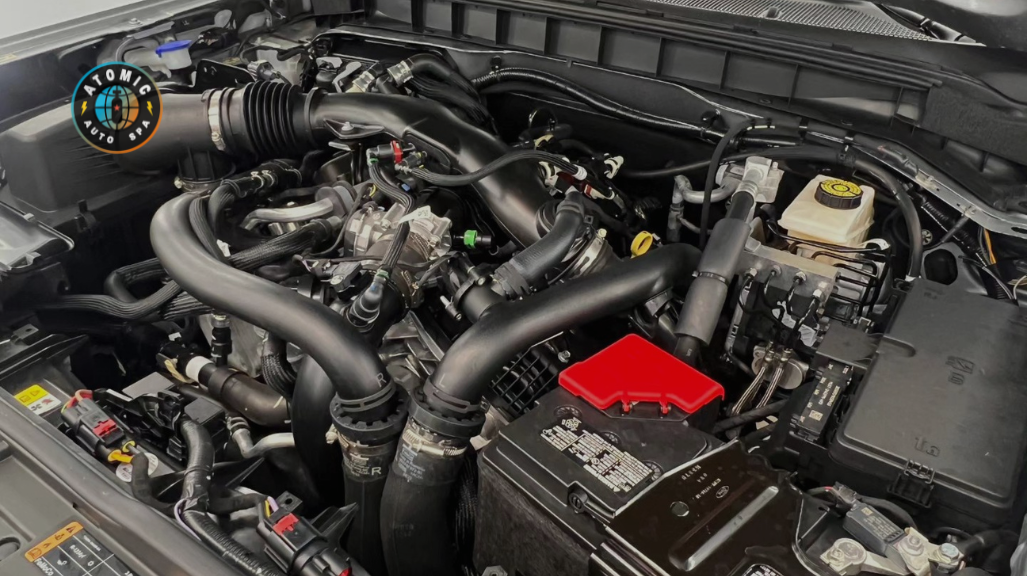

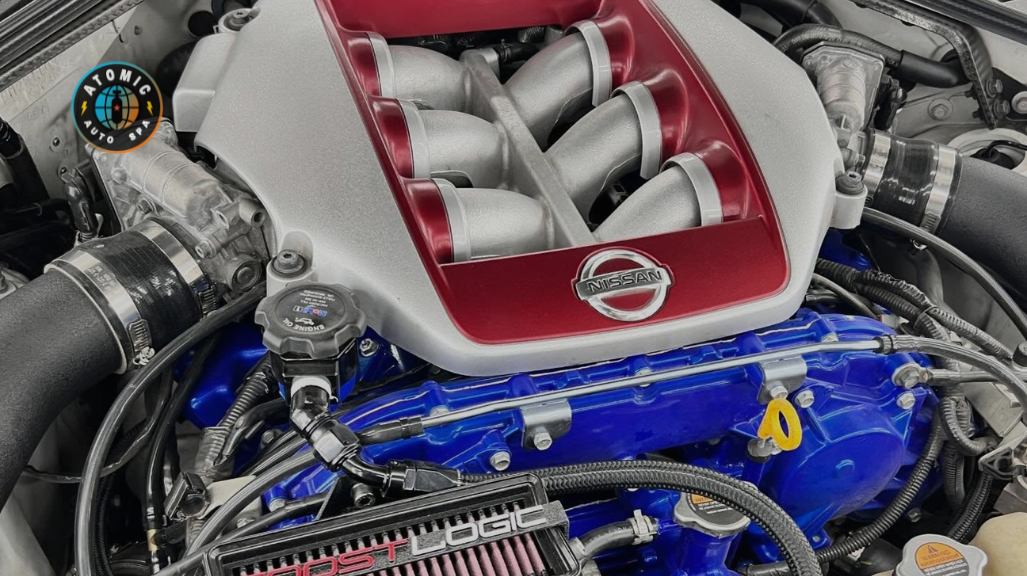

4. Improved Engine Performance and Aesthetics

A clean engine bay isn’t just about looks — it contributes to better vehicle performance.

Reduces heat buildup by removing dirt and debris.

Makes it easier to spot potential issues like leaks or wear.

Enhances resale value by maintaining a pristine appearance.

Comparing Dry Ice Cleaning to Traditional Methods

Dry Ice Cleaning vs. Steam Cleaning

|

Feature |

Dry Ice Cleaning |

Steam Cleaning |

Pressure Washing |

|---|---|---|---|

|

Safety |

Non-abrasive, moisture-free |

Can introduce moisture to wiring |

Uses high pressure, can strip coatings or finishes |

|

Residue |

No residue, dry process |

It may leave water spots or streaks |

Leaves water and chemical residue |

|

Effectiveness |

Excels in removing grease and oil |

Effective but limited for grease |

It is effective but can harm surfaces |

|

Drying Time |

None required |

Requires significant drying time |

Requires significant drying time |

Dry Ice Cleaning vs. Chemical Degreasers

Chemical Risk: Degreasers can damage paint and plastic if not used carefully, while dry ice cleaning is safe for all materials. Additionally, dry ice cleaning is highly effective for cleaning vehicles, efficiently removing dirt and grime without leaving a mess.

Environmental Impact: Dry ice cleaning is residue-free and eco-friendly, whereas degreasers can produce harmful runoff.

Steps in Dry Ice Cleaning an Engine Bay

1. Preparation:

Cover or remove sensitive components like air filters.

Inspect the engine bay to identify heavily soiled areas.

2. Dry Ice Blasting:

Use a dry ice machine to convert dry ice into pellets that create mini-explosions, effectively targeting grease, oil, and dirt without water or chemicals.

Adjust pressure settings for delicate parts like wiring.

3. Post-Cleaning Inspection:

Check for any remaining debris or contaminants.

Reassemble components and test the engine.

Frequently Asked Questions

-

Detailers use various methods to clean engine bays, such as steam cleaning, chemical degreasers, and dry ice cleaning. Dry ice cleaning stands out for its ability to clean without introducing moisture or leaving residues, making it ideal for delicate components.

-

Yes, dry icing, also known as dry ice blasting, is highly effective at removing grease and oil buildup. The thermal shock from the dry ice pellets lifts grease off surfaces without damaging the underlying material.

-

Dry ice cleaning is safe for most vehicles, including modern cars with complex electrical systems and classic cars with delicate components. It’s non-abrasive and doesn’t involve water or chemicals.

-

The time required depends on the condition of the engine bay. On average, dry ice cleaning can take anywhere from 30 minutes to an hour for a thorough job.

-

Yes, dry ice cleaning requires specialized equipment, including a dry ice blasting machine and a reliable source of compressed air. Similar to a pressure washer, which uses water, dry ice cleaning utilizes finely shredded ice pellets to achieve powerful and precise cleaning. Professional detailers are best equipped to perform this service.

Final Thoughts on Engine Bay Detailing with Dry Ice

The dry ice cleaning process has revolutionized engine bay detailing by offering a safe, effective, and eco-friendly method to remove grease, oil, and grime. It outperforms traditional cleaning methods like steam cleaning and chemical degreasers, providing superior results without the risk of damage. For vehicle owners looking to maintain their engine performance and aesthetics, dry ice cleaning is the ultimate solution.

If you’re ready to experience the benefits of dry ice cleaning, contact a professional detailer like Atomic Auto Spa to ensure optimal results.